Başarı Hikayeleri

BAŞARI HİKAYESİ #1:

A WORLD LEADING MANUFACTURER OF SOFT DRINKS

The world leading manufacturer of soft drinks encountered a major problem in the bottle washing unit. The bottles cannot be sterilized completely, and the old labels left a mark.

After contacting Ayvaz, we immediately visited their factories. We examined all the lines, starting from the boiler rooms (CIP, SIP, Bottling, Exchangers, boiling process etc.) and presented our report as a result of reviews. We discovered the problem of condensate draining of heat exchangers in CIP lines. Because of this problem, the heat load in their heat exchangers was 60%. We fixed this problem with ACOP condensate pump application.

We made adjustments to the amount and pressure of steam used in the washing section. Instead of the wrongly chosen steam traps, we replaced with the correct ones. We detected steam leaks in the entire steam line and prevented these leaks with new equipment.

As a result of our efforts, we increased the energy efficiency in the entire factory by 10%.

SBAŞARI HİKAYESİ #2:

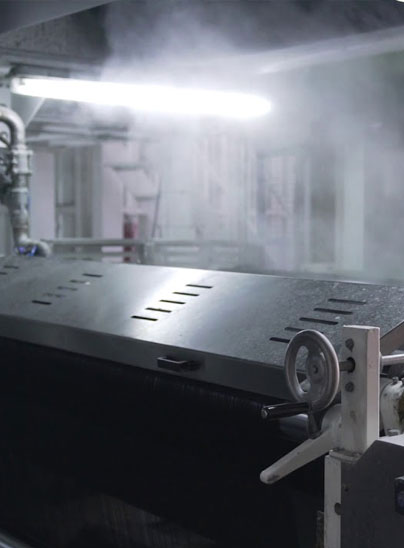

THIS FACTORY MUST WORK IN HARD WEATHER CONDITIONS

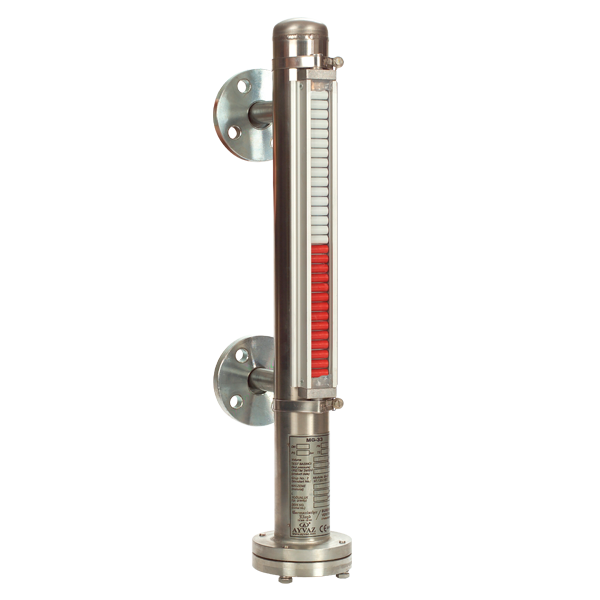

In Nursultan (Astana) - 40 C is the average temperature for the winter. In these weather conditions, the steam lines were not sufficiently insulated, as a result, they lost heat and steam formed condensate.

The excess condensate caused a damage on the steam equipment. Tired of constantly facing with this situation, our valued client asked for support. We prepared report after the audit in the factory. As a result of this study;

- New parts of all missing steam equipment were installed.

- The system was reexamined and PYROGEL insulation was applied for the external lines where there was freezing.

- The evacuation of the condensate was facilitated by correcting the wrong piping in the system.

- Efficiency of the system was increased by 20%.

BAŞARI HİKAYESİ #3:

CORROSION PROBLEM IN PIPES AT A TEXTILE COMPANY IN SERBIA

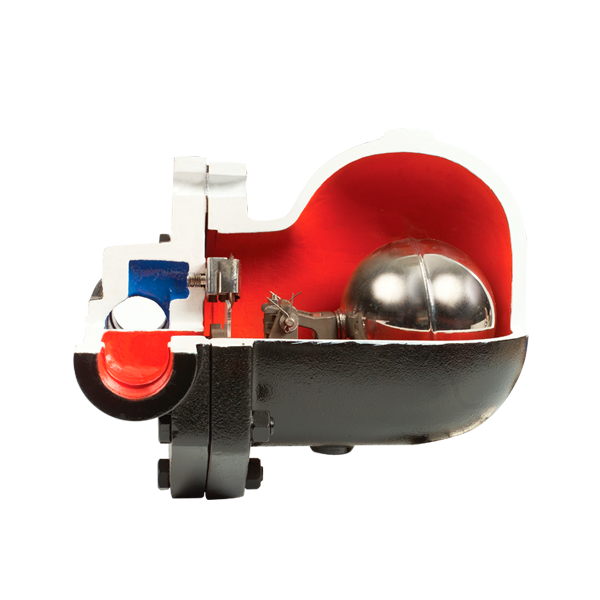

On a phone call to our Serbia Regional Manager, one of our valued customers reported that all steam and condensate pipes had punctures and steam leaks from the gaskets. They stated that they had problems especially with the accumulation of condensate in the dryer cylinders.

After this phone, our Regional Manager and Product Manager visited them. They determined that there was no deaerator in the boiler room, there was not enough blow in the boiler, no vacuum breaker was used in the steam pipes, and the wrong type of steam trap was chosen in the dryers.

A short technical product training was given to our customer.

Following innovations and improvements, deaerators were installed, wrong equipment selections were corrected, blowdown system was installed, vacuum breakers were placed in the system where necessary.

Thus, energy use was reduced by 20%, leaks in pipes and gaskets were prevented. rust problem decreased.

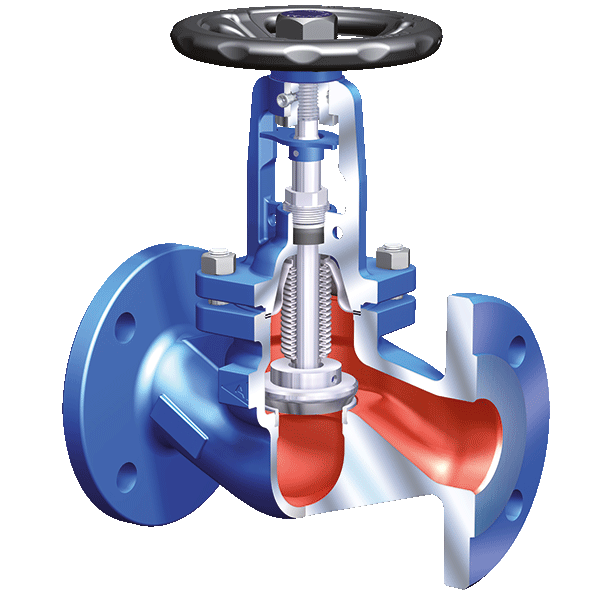

BAŞARI HİKAYESİ #4:

VALVE JACKET APPLICATION IN HUMID ENVIRONMENTS

Due to the various chemicals found in the dye units, especially in the textile industries, the environment is quite acidic and moist. This humidity is approaching 85% levels. this moisture forms drops between pipes and valve insulation jackets. these drops cause corrosion and deformed jackets.

In addition, some jacket materials used at high temperatures may become brittle and shred.

As customer complaints from other brands, as Ayvaz, we started to use special silicone fabric in moist environments in valve jackets and durable glass fiber fabric in high temperature regions.

In addition, we have started to use metal hooks as standard, in case of any deformation that may occur at high temperatures in velcro bands.

Thus, the service life of valve insulation jackets increased by 30%.